ASES – Australia

Unit 8,

5-7 Wiltshire Street,

MINTO, NSW, 2566, Australia

Phone: +61 2 9933 4900

Email Information:

Sales:

info@ases.co

Support:

support@ases.co

Accounts:

accounts@ases.co

General:

info@ases.co

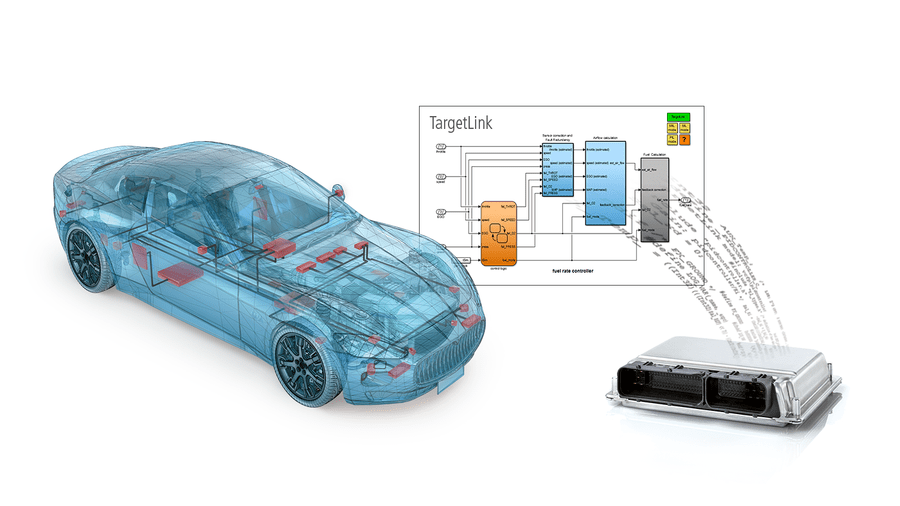

The production code generator TargetLink generates highly efficient C code straight from MathWorks® Simulink®/Stateflow® and allows early verification through built-in simulation and testing. It supports efficient, modular development, is certified for ISO 26262, ISO 25119 and IEC 61508, and provides high-performance, native AUTOSAR support.

Model-based design has become the established development method across many industries, and production code generation is the logical step for turning models into efficient, production-ready code. TargetLink generates production code (C code) straight from the Simulink/Stateflow graphical development environment. The C code generation options range from plain ANSI C code to optimized fixed- or floating-point code for AUTOSAR platforms. Versatile code configuration options ensure that the production code can handle processor constraints.

With TargetLink, you can convert graphical models directly and deterministically into highest quality production code. Benefit from TargetLink’s numerous strenghths, such as:

| Feature | Description | Benefit |

| Code efficiency | Efficient fixed-point or floating-point production code directly from Simulink®/Stateflow® (with support for included MATLAB code, see optional module) | Your specifications – models and diagrams – are directly translated into efficient C code |

| Code reliability | Consistent, deterministic translations of models into stress-tested C code | Errors such as typing errors, oversights, misunderstandings are avoided |

| Human readability | Concise, yet readable code | Code reviews are easy to perform |

| Automatic scaling | Intelligent scaling based on worst-case propagation of signal ranges and simulation-based scaling | Shortens the time-consuming and error-prone scaling process |

| Test mechanisms | Various test levels to test the production code against the specification (MIL, SIL, PIL) | Malfunctions are found at the earliest stage |

| Incremental code generation | Modular code generation, i.e., for specific subsystems | Faster code generation, preserving approved code |

| Model referencing support | Developing models on a modular/component basis | Distributed development by large teams is much easier, and large models can be handled more efficiently. |

| Multirate code | Full support of multirate systems with intertask communication | You can define tasks at block level |

| TargetLink Data Dictionary | Central container to handle variables, data structures, scaling formulas, tasks, functions | You can manage complex data to plan and structure your projects |

| Code generation straight from the Data Dictionary | Generation of code files and A2L files for Data Dictionary variables independently of their use in TargetLink models | Simplified software integration and integration testing for code from multiple TargetLink models/subsystems and legacy variables |

| ‘Modeling Only’ and ‘Full-Featured’ operation modes | The Modeling Only operation mode (not licence-protected) lets function developers prepare and design a model without generating production code for it. | Easy model exchange in a workgroup (Simulink® and TargetLink users) |

| Compliance with standards | Compliance with relevant standards such as ASAM-MCD 2MC (ASAP2), AUTOSAR, and MISRA | Quality and interoperability guaranteed |

| Classic AUTOSAR support | Support for modeling and code generation for AUTOSAR software components (SWC), and generation of SWC descriptions | TargetLink bridges the gap between model-based design and AUTOSAR-compliant software development |

| Adaptive AUTOSAR support | Support for modeling and code generation for Adaptive AUTOSAR-compliant C/C++ code (for information on supported features, please contact dSPACE) | Closely resemblant modeling styles for non-, Classic and Adaptive AUTOSAR |

| Simple and convenient Adaptive AUTOSAR code generation | ||

| Calibration data generation | Calibration data exported as ASAM-MCD 2MC (ASAP2) file for calibration tools | Automated and complete process with perfect consistency between model and calibration data |

| Documentation | Automatic model and code documentation | Your projects are transparent and trackable |

| AUTOSAR software component (SWC) container exchange | Exchanging AUTOSAR SWC containers between TargetLink and SystemDesk | Safe and convenient round trips for AUTOSAR software development |

| Access to SystemDesk simulation for proper software integration testing | ||

| Component-based development | Innovative interface concept for ports, measurement signals and calibration parameters | Easily increase software reuse across different projects |

| Connection to dSPACE VEOS | Export virtual ECUs from TargetLink and run them in VEOS in combination with other virtual ECUs and standard dSPACE tools like ControlDesk | Easy testing and experimenting with TargetLink code |

| FMI support | Export of Functional Mock-up Units (FMUs) from TargetLink models based on the Functional Mock-up Interface (FMI) standard | Execution of TargetLink-generated code with offline and real-time simulators from third parties and dSPACE |

| On-Target Bypassing | Integrating new functions directly into existing ECUs (using TargetLink and dSPACE ECU interface software) | Seamless transition from prototyping to series production |

| No need to perform complex software integration |